Understanding Styrene-Butadiene Copolymer Resins: A Comprehensive Guide

Styrene-Butadiene Copolymer Resins, commonly known as SBC resins, play an essential role in a wide range of modern industrial and consumer applications. These thermoplastic elastomers combine the beneficial properties of both rubber and plastic, offering excellent elasticity, clarity, processability, and impact resistance. In this complete guide, we will delve into what SBC resins are, how they are made, their different types, unique characteristics, performance advantages, common uses, and what to consider when selecting or working with them.

Content

- 1 What Are Styrene-Butadiene Copolymer Resins?

- 2 How Are SBC Resins Produced?

- 3 Types of Styrene-Butadiene Copolymer Resins

- 4 Advantages of Using SBC Resins

- 5 Common Applications of SBC Resins

- 6 Processing Methods

- 7 How to Choose the Right SBC Resin

- 8 Environmental and Regulatory Considerations

- 9 Conclusion

What Are Styrene-Butadiene Copolymer Resins?

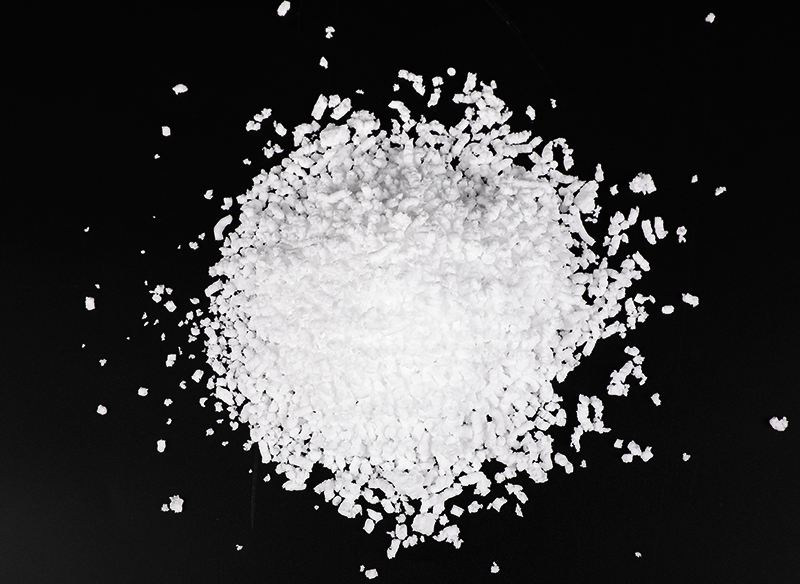

Styrene-Butadiene Copolymer Resins are block copolymers composed primarily of styrene and butadiene monomers. These resins belong to the broader class of thermoplastic elastomers (TPEs), meaning they exhibit both thermoplastic (melt-processable) and elastomeric (rubber-like) behavior.

Typically, an SBC has a structure represented as S-B-S (styrene-butadiene-styrene) or S-EB-S (styrene-ethylene-butylene-styrene). These triblock structures consist of two hard polystyrene end blocks and a soft, rubbery mid-block made from butadiene or a hydrogenated version like ethylene-butylene. This combination allows SBC resins to behave like vulcanized rubber at room temperature but be reprocessed like plastics when heated.

How Are SBC Resins Produced?

The production of SBC resins involves a technique called living anionic polymerization, where monomers are added sequentially in a controlled manner to form distinct blocks:

-

Initiation: A catalyst initiates the polymerization of the styrene monomer.

-

Propagation: Once the polystyrene block is formed, butadiene is introduced to form the soft, elastic mid-block.

-

Termination: A final addition of styrene forms the outer hard segment, resulting in the triblock copolymer.

Some versions undergo hydrogenation to improve their stability, particularly for applications involving heat or UV exposure.

Types of Styrene-Butadiene Copolymer Resins

There are several variants of SBC resins, each with tailored performance characteristics for specific applications:

1. SBS (Styrene-Butadiene-Styrene)

Widely used in adhesives, footwear, and construction.

Offers high elasticity and flexibility.

Excellent for hot-melt adhesive applications.

2. SEBS (Styrene-Ethylene-Butylene-Styrene)

Hydrogenated version of SBS with improved weather and thermal resistance.

Used in medical devices, personal care products, and automotive parts.

3. SIS (Styrene-Isoprene-Styrene)

Offers superior tack and adhesion.

Commonly used in pressure-sensitive adhesives and packaging tapes.

4. Other Blends and Modifications

Custom blends with polyolefins, polystyrene, or polypropylene for enhanced mechanical and processing characteristics.

Key Characteristics of SBC Resins

| Property | Description |

| Elasticity | Exhibits rubber-like flexibility and stretchability |

| Clarity | Transparent and glossy appearance in film and molded forms |

| Processability | Easy to mold, extrude, and blend with other polymers |

| Recyclability | Thermoplastic behavior allows re-melting and reuse |

| Adhesion | Excellent for making pressure-sensitive and hot-melt adhesives |

| Weather Resistance | Especially good in hydrogenated forms like SEBS |

Advantages of Using SBC Resins

Styrene-Butadiene Copolymer Resins offer a balance of performance and cost-effectiveness, making them a popular material across industries. Some notable benefits include:

Versatility: Suitable for rigid and flexible applications

Soft Touch Feel: Ideal for grips, toys, and medical products

Good Impact Strength: Enhances durability in plastic blends

Lightweight: Lower density than many other rubber materials

Excellent Adhesion: Allows bonding to diverse surfaces without the need for primers

Common Applications of SBC Resins

SBC resins are used in a wide array of sectors due to their adaptable properties:

1. Adhesives and Sealants

Hot-melt adhesives (HMAs)

Pressure-sensitive adhesives (PSAs)

Construction sealants

2. Packaging and Films

Food-safe stretch films

Blister packaging

Shrink labels and sleeves

3. Medical and Personal Care

Syringe plungers

Catheters and tubing

Toothbrush grips

Razor handles

4. Consumer Goods

Footwear components

Toys and sporting goods

Soft-touch electronics casings

5. Automotive and Industrial

Instrument panel skins

Door trim and gaskets

Wire and cable insulation

6. Compounding and Modification

Used as impact modifiers in polystyrene and polypropylene blends

Enhances tactile quality and strength of polymer compounds

Processing Methods

SBC resins are compatible with standard thermoplastic processing techniques, including:

Injection Molding

Extrusion

Blow Molding

Thermoforming

These methods allow for high-speed production and flexibility in design, supporting both large-scale industrial uses and fine-detailed consumer goods.

How to Choose the Right SBC Resin

When selecting a styrene-butadiene copolymer resin for a specific application, consider the following criteria:

| Requirement | Recommended SBC Type |

| High elasticity | SBS, SIS |

| Heat resistance | SEBS (hydrogenated) |

| UV/weather resistance | SEBS |

| High clarity | SBS |

| Excellent tackiness | SIS |

| Biocompatibility | Medical-grade SEBS |

| Chemical resistance | SEBS with proper compounding |

Environmental and Regulatory Considerations

As demand grows for environmentally conscious materials, SBC resins are increasingly being formulated to meet various regulatory and sustainability standards:

FDA compliance for food contact applications

REACH and RoHS compliance for electronics and medical use

Recyclability in thermoplastic processing

Low VOC emissions for adhesives and sealants

Some manufacturers are also exploring bio-based versions and post-consumer recycling of SBC-containing products to reduce environmental impact.

Conclusion

Styrene-Butadiene Copolymer Resins represent a unique class of materials that offer the best of both the plastic and rubber worlds. Their adaptability, performance, and cost-efficiency make them indispensable in industries ranging from packaging and medical devices to automotive parts and adhesives. By understanding the different types, characteristics, and uses of SBC resins, manufacturers and designers can make informed choices that align with performance requirements, regulatory standards, and environmental goals.

Whether you're developing a new consumer product, enhancing polymer formulations, or sourcing materials for industrial manufacturing, SBC resins offer a flexible and reliable solution for modern material challenges.