Hydrogenated Styrene-Butadiene Block Copolymer: Enhancing Material Performance Across Industries

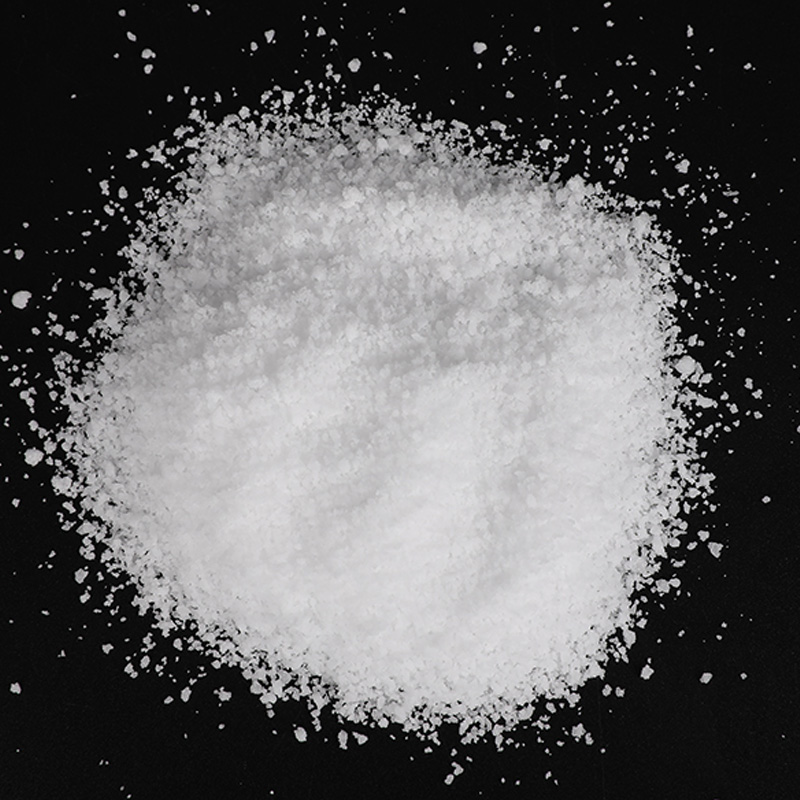

Hydrogenated Styrene-Butadiene Block Copolymer (commonly referred to as HSBC or SEBS when ethylene and butylene are the mid-blocks) is a versatile thermoplastic elastomer widely used in applications that require a balance of elasticity, durability, and weather resistance. This material combines the properties of rubber and plastic, offering manufacturers a lightweight, flexible, and processable solution for high-performance products.

This article provides practical insights into HSBC’s key characteristics, applications, and benefits, helping engineers, product designers, and procurement specialists make informed decisions.

What Is Hydrogenated Styrene-Butadiene Block Copolymer?

Hydrogenated Styrene-Butadiene Block Copolymer is produced by hydrogenating a styrene-butadiene-styrene (SBS) or styrene-isoprene-styrene (SIS) base. This chemical modification significantly enhances the material’s thermal stability, oxidative resistance, and UV durability. The result is a more robust, weather-resistant elastomer suitable for demanding environments.

HSBC typically consists of:

- Hard Styrene Blocks (S) – provide structural integrity and thermoplastic behavior

- Soft Butadiene (or Isoprene) Blocks (B or I) – contribute to elasticity and rubber-like softness

- Hydrogenation – saturates the double bonds in the rubber segment, increasing resistance to aging, heat, and weather

Key Advantages of HSBC

Hydrogenated SBCs offer a number of material benefits:

1. Excellent Weather and UV Resistance

Unlike unhydrogenated rubber, HSBC performs reliably in outdoor conditions. It resists cracking, yellowing, and loss of mechanical strength from prolonged UV exposure.

2. Superior Thermal Stability

Withstanding higher processing and operating temperatures, HSBC maintains performance without degradation under heat, making it suitable for automotive and electrical uses.

3. Outstanding Flexibility and Softness

It combines the flexibility of rubber with thermoplastic processability, enabling comfortable and ergonomic product designs, especially in consumer goods and medical products.

4. Chemical and Aging Resistance

Hydrogenation significantly improves resistance to oxidation, ozone, and many chemicals, ensuring long-term durability in harsh environments.

5. Processability

HSBC can be processed using conventional plastic manufacturing methods, including injection molding, extrusion, and blow molding. It can also be blended with other polymers to optimize cost and performance.

Common Applications Across Industries

Hydrogenated Styrene-Butadiene Block Copolymers are used in a wide range of industries:

● Automotive

Used for interior trim, seals, gaskets, and soft-touch components due to its low odor, UV stability, and abrasion resistance.

● Consumer Goods

Ideal for soft-grip handles, shoe soles, personal care items, and toys. HSBC provides a pleasant tactile feel and meets safety regulations.

● Medical Devices

Due to its biocompatibility and sterilization resistance, HSBC is used in tubing, grips, and components in contact with skin or fluids.

● Electrical & Electronics

Cable sheathing and connectors benefit from HSBC’s insulation properties, flexibility, and resistance to heat and flame.

● Adhesives & Sealants

HSBC serves as a base polymer in pressure-sensitive adhesives and sealant formulations, offering cohesive strength and flexibility.

Selecting the Right Grade

HSBC is available in various molecular weights, styrene content, and block configurations, allowing for customization based on:

- Hardness and Elasticity Requirements

- Clarity or Opacity

- Colorability

- Thermal or Chemical Resistance

- Regulatory Compliance (e.g., FDA, RoHS)

Blending with polypropylene, polyethylene, or oils can further tune the performance to meet specific industry or product needs.

Sustainability Considerations

HSBC is recyclable in many applications and can replace thermoset rubber in certain use cases, reducing environmental impact. Additionally, ongoing R&D is focused on bio-based alternatives and improving processing efficiency to support sustainable manufacturing goals.

Hydrogenated Styrene-Butadiene Block Copolymer offers a powerful combination of flexibility, durability, and environmental resistance. For businesses seeking advanced material solutions that bridge the gap between plastics and rubber, HSBC provides an adaptable platform for innovation.

Whether you're developing automotive interiors, medical components, or consumer products, choosing the right grade and formulation of HSBC can help you enhance product performance, reduce costs, and meet regulatory standards. Its processability and long-term reliability make it a material worth considering in today's performance-driven market.